Email: info@rado-tech.co.uk

Email: info@rado-tech.co.uk

In this section:

Rado-Tech Reverse Engineering presents customers with an alternative for new equipment. Rado-Tech can Reverse Engineer expensive OEM Equipment and provide a less expensive alternative which will meet Customer requirements.

What is Reverse Engineering?

Reverse engineering is the process of collecting data from a piece of equipment, object or system through the analysis of its structure, function and operation, often when there is no digital data available to analyse. It often involves deconstructing an object and analysing its workings in detail.

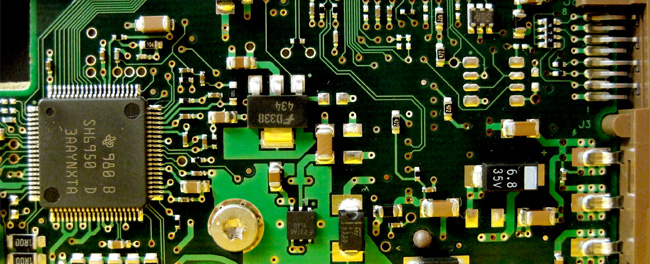

Electronic Obsolescence: Reverse Engineering of electronic circuits for equipment control are often designed on obsolete, proprietary OEM systems, which can mean that the only way to incorporate the new equipment functionality is to reverse-engineer the existing electronic circuit and then re-design it.

Legacy Software Improvement: Reverse Engineering of legacy software which is no longer supported by equipment OEM's can provide many benefits to extend equipment operational lifetime. Another benefit of software reverse-engineering is to eliminate bugs which could exist in legacy software.

Documentation Improvement: Reverse Engineering can be used when documentation for a piece of equipment, production, operation or maintenance have shortcomings and the original designers/manufacturers are not available. Reverse Engineering of software can provide the most current documentation necessary for understanding Equipment operation.

Equipment Optimisation: Reverse Engineering can help to optimise existing equipment performance by identifying the equipment limitations and therefore present redesign/upgrade opportunities to improve equipment performance.

If any of these problems exist in your company, Rado-Tech can help!